Ever wondered how metal parts are made? From tiny jewelry to massive engine parts, metal casting shapes the world around us. It’s a powerful process that turns molten metal into strong, precise, and useful objects.

Whether for art, construction, or manufacturing, metal casting offers endless possibilities. Let’s explore how this process brings ideas to life in so many industries!

Different Types of Metal Casting Methods

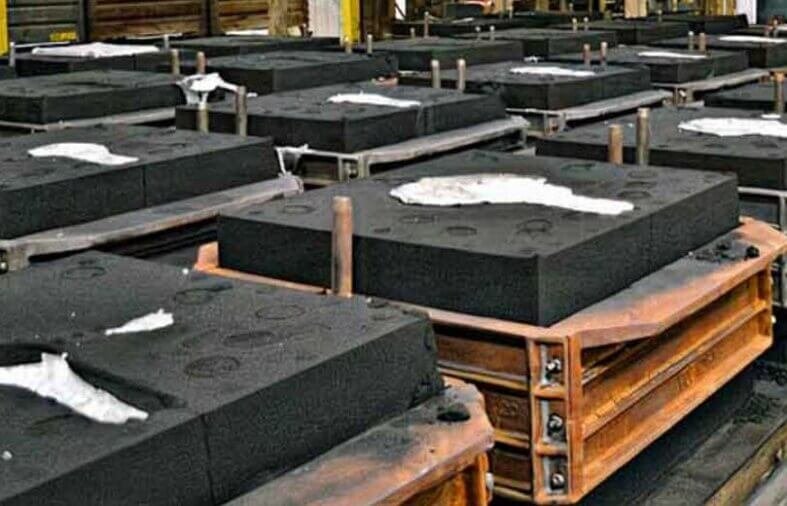

There are several types of metal casting methods, each suited for different needs. Sand casting is a common method that uses a sand mold to shape the metal, making it ideal for large or complex parts.

Die casting forces molten metal into a steel mold under high pressure, creating smooth and precise parts, perfect for mass production. 304 stainless steel investment casting is a type of lost-wax casting, which uses a wax model coated in ceramic to create highly detailed and strong parts.

Centrifugal casting spins molten metal inside a mold to form hollow cylindrical shapes, like pipes and rings. Each casting method offers unique advantages, making metal casting a versatile process for industries like automotive, aerospace, and construction.

Common Metals Used in Casting

Different metals are used in casting depending on strength, durability, and cost. Aluminum is a popular choice because it is lightweight, resistant to rust, and easy to mold.

Cast iron is strong and heat-resistant, making it ideal for engine parts and cookware. Steel, including stainless steel, is used for tough and corrosion-resistant parts in construction and machinery.

Bronze and brass are also common, often used for decorative pieces, musical instruments, and marine parts due to their resistance to corrosion.

Applications in Manufacturing and Industry

Metal casting is widely used in manufacturing and industry to create strong and precise parts. It is used in the automotive industry to make engine blocks, gears, and brake components.

Construction companies rely on cast metal for building frames, pipes, and tools. In aerospace, metal casting helps produce lightweight yet durable aircraft parts. Many industrial machines also use cast metal components for better strength and performance.

Artistic and Decorative Uses of Metal Casting

Metal casting is popular in art and decoration because it creates detailed and durable designs. Artists use it to make sculptures, statues, and custom jewelry.

Many home decorations, like candle holders and wall art, are made with cast metal. Bronze and aluminum are common choices for artistic casting due to their strength and beauty. This process allows creators to design unique and long-lasting pieces.

Advantages of Metal Casting in Modern Production

Metal casting is a key process in modern production because it allows for complex shapes and detailed designs. It is cost-effective, especially for mass production, since it reduces material waste.

Strong and durable metal parts can be made for industries like automotive and construction. The process works with many metals, offering flexibility in manufacturing. Metal casting also ensures consistent quality, making it a reliable choice for modern production needs.

Learn All About Versatility of Metal Casting

Metal casting is a powerful process that shapes everything from industrial parts to artistic designs. It offers strength, precision, and flexibility for many industries. With different methods and materials, it meets a wide range of needs.

Whether for manufacturing or art, metal casting remains an essential technique. Its versatility makes it a valuable part of modern production.

Visit our blog for more!