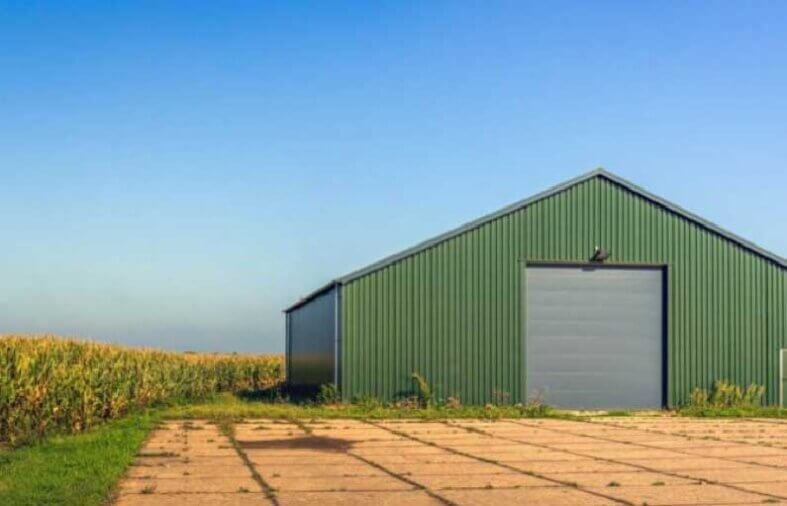

When it comes to efficient storage solutions for rural settings, metal barns stand out as a top choice. Their durability and versatility make them ideal for housing everything from tractors to livestock. As a farmer or rancher, I know the importance of protecting valuable equipment and animals from the elements, and metal barns offer a reliable solution.

These structures, built from prefabricated steel components, provide a cost-effective alternative to traditional construction. With their rust-resistant coatings and robust frames, metal barns withstand harsh weather conditions, reducing the need for constant maintenance. This means I can focus more on my work and less on repairs.

Customizing a metal barn to fit specific needs is another key advantage. Whether it’s adding overhead storage or climate control systems, the possibilities are nearly endless. By choosing metal barns, I’m investing in a storage solution that’s not only practical but also adaptable to future needs.

Importance of Efficient Storage in Metal Barns

Efficient storage in metal barns is crucial for optimizing resource use and enhancing operational efficiency. With their durability, metal barns offer reliable protection for valuable equipment, livestock and supplies against extreme weather conditions. This protection minimizes potential damage or loss, which is pivotal for maintaining productivity and controlling costs in rural operations.

Maximizing the use of space is another compelling aspect of efficient storage in these structures. The clear-span design of metal barns provides large, unobstructed interiors, accommodating varied storage needs like machinery, feed and tools. This flexibility ensures that every square foot is used effectively, reducing clutter and facilitating easier access to essential items.

Customization enhances efficiency further by allowing the addition of specialized features such as shelving, overhead storage and dedicated climate control. These options cater to specific requirements, whether for keeping feed fresh or storing sensitive equipment. For instance, incorporating metal building insulation rolls can significantly improve temperature regulation, making the barn energy efficient while protecting contents from temperature fluctuations.

Reduced maintenance requirements contribute to long-term practicality. Unlike wooden structures which need regular weatherproofing, metal barns require minimal upkeep, saving time and resources. This low-maintenance aspect ensures that valuable effort is focused on core agricultural activities rather than constant repairs.

Incorporating efficient storage solutions in metal barns isn’t just about maximizing space; it fundamentally supports the seamless and successful management of rural properties. When properly optimized, these structures enhance productivity, streamline operations and provide a robust shelter capable of adapting to evolving storage needs.

Assessing Your Storage Needs

Determining the right storage solutions begins with understanding your specific requirements. Consider available space, key items, and priorities for storing to optimize metal barn efficiency.

Measuring Available Space

Accurate measurement of barn space ensures effective storage solutions. First, measure floor area and ceiling height. A clear understanding allows for better planning and use of space, considering whether multiple levels or overhead storage systems might be installed. Next, identify potential obstructions like beams or support posts that might affect storage layout. Lastly, evaluate accessibility of doors and windows to ensure easy movement of items. Comprehensive assessment helps in designing a storage plan that maximizes space utility.

Identifying Key Storage Items

List essential items for storage to tailor the barn’s setup to specific needs. Common items include farming tools, machinery, feed, and livestock supplies. Next, assess each item’s size, frequency of use, and protection needed. For example, consider whether machinery requires climate control or if tools need quick access for daily operations. By identifying and categorizing items, I can prioritize space allocation and design appropriate storage units.

Establishing Usage Priorities

Determining usage priorities supports a functional storage system. First, rank items by usage frequency; frequently used items should be more accessible. Next, consider seasonal requirements. For instance, equipment used only during planting should be stored differently than everyday tools. Lastly, weigh the need for climate-controlled storage for sensitive materials, considering options like metal building insulation rolls. Prioritizing tasks this way streamlines barn operations and enhances overall efficiency.

Types of Storage Solutions for Metal Barns

Exploring storage solutions enhances the usability of metal barns by leveraging their spacious interiors efficiently. Several options cater to different storage needs in rural settings.

Wall-Mounted Shelving Units

Wall-mounted shelving units maximize vertical space, keeping the floor clear in metal barns. Sturdy, rust-resistant metal shelves withstand substantial weight and exposure to weather elements. When I install these units, not only do they help organize tools and supplies, but they also free up valuable floor space for larger equipment. Vertical shelving structures like these provide a scalable solution, fitting seamlessly into any barn setup while ensuring easy access to frequently used items.

Pegboards and Tool Racks

Pegboards and tool racks offer flexible storage solutions for organizing tools and smaller equipment. These perforated panels allow for customizable arrangements with hooks and brackets. When I use pegboards, it creates a neat display where everything from hammers to pliers is within arm’s reach. Adaptable tool racks can be adjusted as needs change, making them ideal for dynamic environments like farms where accessibility and organization drive efficiency.

Overhead Storage Systems

Overhead storage systems utilize ceiling space to store infrequently used or bulky items. By incorporating these systems into my metal barn, I can keep seasonal equipment or excess inventory off the ground, maximizing the available floor area for active use. These systems include hoists or platforms, offering an innovative way to declutter the barn and improve operational flow. Designing them to handle substantial loads ensures safety while enhancing storage capacity.

Free-Standing Shelves

Free-standing shelves provide versatile storage solutions with the flexibility to move and reconfigure as needed. Available in various sizes and designs, these shelves accommodate everything from hay bales to machinery parts. Their modular nature allows me to rearrange or expand units based on shifting storage requirements. Investing in durable free-standing shelves means an adaptable barn environment that evolves with changing agricultural demands, helping maintain order and accessibility.

Organization Tips for Maximizing Space

Efficient organization in metal barns significantly enhances storage capacity and accessibility. These strategies ensure a streamlined, functional layout that meets various storage needs.

Using Clear, Labeled Containers

Seeing what’s inside containers at a glance saves time and reduces frustration. Clear storage containers make it easy to identify contents without opening them, allowing quick inventory assessments. To elevate organization, integrating a labeling system categorizes items by type or use. Labels like “Holiday Decorations” or “Power Tools” simplify item retrieval and maintaining order. Consistent labeling minimizes the chance of misplaced items, ensuring your barn stays organized and clutter-free.

Implementing Vertical Storage

Maximizing vertical space in a barn frees up valuable floor area. Installing wall-mounted racks and ceiling hooks accommodates items such as bicycles and tall ladders. Hanging equipment prevents damage and keeps the barn tidy. Employing ladder hooks and overhead racks for heavier items like metal building insulation rolls securely stores them while keeping them accessible. This method optimizes both space use and item safety within your barn.

Creating Distinct Zones for Different Items

Designating specific zones for types of items streamlines organization. Divide the barn into clear sections for categories like tools, equipment, and seasonal gear. This method improves the efficiency of storing and retrieving items. Usage frequency should guide the placement, with regularly used items at the front and seasonal or infrequent items stored further back. By establishing dedicated spaces for different items, navigating your barn becomes intuitive and efficient, supporting a well-ordered storage environment.

Factors to Consider When Choosing Storage Options

When selecting storage systems for metal barns, evaluating key factors ensures efficiency and longevity.

Material Durability and Maintenance

Choosing durable materials is crucial for long-lasting storage solutions in metal barns. Prioritizing rust and corrosion-resistant options increases the longevity of shelves and storage units, minimizing maintenance needs. Metal shelving units often meet these criteria, providing stability and resilience in various weather conditions. Regularly inspecting for wear and tear ensures the structural integrity of the storage systems, which prevents unexpected failures.

Weight Capacity and Safety

Assessing the load-bearing capacity is vital to sustaining safe storage practices. Each storage option should support the weight of intended items, including heavy tools and machinery, without compromising stability. Overloading shelves can result in structural failures, posing safety risks. Tools like torque wrenches and clamps should enhance secure installation, ensuring the safety and effectiveness of the storage setup.

Flexibility and Customization

Customizable storage solutions enhance the adaptability of metal barns to meet specific needs. Shelving units that allow easy rearrangement support changing storage demands throughout the year. Features such as adjustable shelves, partitioned bins, and modular designs provide flexibility. This adaptability is crucial for managing seasonal equipment and supplies efficiently, ensuring the barn remains organized and functional.

Common Mistakes to Avoid

When optimizing storage in rural metal barns, avoiding certain pitfalls ensures better space utilization and longevity.

Overloading Shelves

Exceeding a shelf’s weight limit risks damage and item loss. Metal barns often house heavy equipment and supplies, making it crucial to distribute weight evenly across shelving units. To prevent overloading, I check the manufacturer’s weight guidelines and select shelves designed to handle the load. Spacing heavier items equally mitigates the risk of tipping or collapsing. Regularly reviewing and redistributing stored items maintains balance and safety.

Neglecting Accessibility

Efficient storage prioritizes ease of access. Poorly planned layouts hinder item retrieval and can lead to misplaced tools. In metal barns, I arrange items based on usage frequency, positioning frequently-used tools within easy reach. Clear labeling and organized pathways further enhance accessibility. I avoid blocking access points with bulky items and always keep walkways clear to facilitate swift, unhindered passage.

Ignoring Ventilation Needs

Ventilation significantly impacts stored items’ preservation, especially in metal barns where condensation is a concern. Without adequate airflow, moisture build-up leads to rust, corrosion, and mold. Installing vents or using metal building insulation rolls mitigates these risks by controlling temperature fluctuations. To ensure proper ventilation, I regularly check barn openings and minimize obstructions that impede air circulation, preserving both structural integrity and stored items.