CNC machining is among the most commonly practiced processes in the modern industry. If you are a first-time reader, or if you need more information about this critical process, you’re in the right place. Here in this easy-to-understand guide about CNC machining, we will explain what it is, the categories of the processes involved, the materials used, and applications among others. In summary, at the end of this article, you can understand the whole process of CNC machining as well as how to select the right CNC machining partner.

What is CNC Machining?

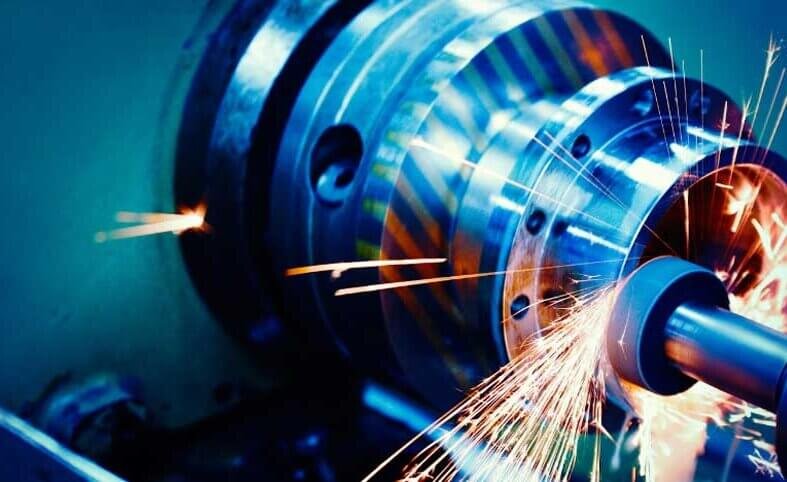

CNC (Computer Numerical Control) is a manufacturing process through which computerized equipment is used to produce parts and other structural products. They can slice, bore, and model materials such as metal, plastics, as well as wood. As previously illustrated, the beauty of this process of product development known as CNC machining is the ability to achieve high accuracy in the final product. The tools introduced by computers help the manufacturers achieve great precision, and the tolerance level is extremely small.

In other words, it automates manufacturing technology hence making it efficient, accurate, and much faster than manual work. This technology is applied in almost all sectors including automobile, aircraft manufacturing, and electronics.

The Categories of CNC Machining Operations

CNC machining encompasses a large number of operations that are relevant to a variety of applications. Here are the most common ones:

- CNC Milling: In this process, a cutting tool that rotates in motion cuts through a workpiece in order to shape it. It is most appropriate for preparing fine patterns and shapes.

- CNC Turning: This process is employed especially in the production of cylindrical components. The material rotates while a cutting tool forms around it and is very suitable for making shaft bolts.

- CNC Drilling: This process is literally as the name suggests as it entails the making of holes in a material. The tool is widely utilized where fine boring is necessary, for example, for the making of a hole for screws or pipes.

- CNC Grinding: This process employs a revolving wheel that tears the truncated surface to make it even or attain a desirable sharpness. It can also be used to complete the parts to the required low rough surface or high edge condition.

Every one of these CNC machining options has a specific application based on the challenging projects.

CNC Machining Materials

Normally, CNC machining can operate on almost all materials; this makes it very flexible. Here are some of the most common materials used:

- Metals: Aluminum, steel, brass, and titanium are some of the popular materials that are often used in CNC machines due to their hardness. The most common wrapped material today is aluminum because despite being light, it is strong.

- Plastics: CNC machines are also compatible with part types of materials such as ABS, polycarbonate, nylon, etc. These materials are finding applications in products like housings brackets and casings.

- Wood: However, CNC machining, on wood, is rare, though used where the wood is to be made into a part or any decorative item.

Materials are selected for various reasons ” They are dependent on the particularity of the part including the strength, durability together with heat and wear resistances.

CNC Machining Applications

CNC machining is applied widely as it can create parts with high accuracy and intricate design. Here are some of the primary applications:

- Automotive Industry: CNC is involved in the production of engine parts, transmission parts car accessories, and many other parts of cars. This helps keep the level of precision necessary for these components to work as they should, intact.

- Aerospace Industry: Thus aerospace, even a tiny component has to adhere to certain levels of quality. CNC machining is appropriate for any challenging aircraft fabrication prosecutions like turbines, wing components, and engine parts.

- Medical Industry: CNC machining is employed in the production of medical devices, surgical tools, and implants among others. High precision and compatibility with the material used in medical applications make use of CNC machining crucial in this sector.

- Electronics Industry: Tiny intricate components that are utilized in computers, smartphones, and other gadgets are produced through aspects of CNC Machining.

Given these diverse applications, it is obvious why many machining services are necessary in manufacturing companies.

Advantages of CNC Machining

That is why CNC machining is relevant to many industries. Here are some of its key advantages:

- Precision: CNC machines can produce intricate and exact physical parts of a product, which makes the machines suitable for sectors that have small clearances.

- Speed: In the case of guided machines, the management of the manufacturing process through computers reduces the time taken to do so. This means that parts can be made fairly rapidly and at the same time can be made with precision.

- Efficiency: Compared to manual machines, CNC machines require little or no supervision during operations especially at night resulting in higher production and huge cost savings.

- Versatility: Some of the advantages of CNC machining have already been mentioned, but it needs to be recalled that this technology can work with a large number of materials and make shapes that are almost impossible to create manually.

- Consistency: They can replicate the same part time and again and the accuracy of the parts will be exactly similar, once a design is fed into the CNC machine.

How to Select the Appropriate CNC Machining Company

Selecting a suitable CNC machining partner is very important since your parts should be of the right quality and standard as required. Here are a few things to consider when selecting machining services:

- Experience and Expertise: Ensure that the company does this kind of machining to avoid handling a complex task for a company with no experience in the type of machining you need. They should have exclusive knowledge on how to handle the materials and then fashion out the parts to your desires.

- Equipment: First of all, one needs to learn if the company presently uses CNC machines and if they are updated. Technology gives high accuracy, selection, and uninterrupted work.

- Quality Control: The company must also have a very rigid quality assurance policy for the parts that it sells to make sure that none of them is substandard.

- Turnaround Time: Lead time is usually very important in manufacturing, therefore it is important to see that the company can supply parts within the required time.

- Customer Support: An ideal partner should have smooth communication and good customer relations during the assignment.

Final Words

CNC machining is a shop floor production technique that has gained widespread application in today’s production lines due to its accuracy, efficiency, and adaptability. Whether you are in the automotive, aerospace, or electronics business, CNC machining allows you to machine very complex geometry and very accurate parts with relative ease. When it comes to CNC machining, with knowledge of the types of processes, materials used, and application areas, decision-making in pursuing upcoming projects will not be a problem.

It is essential to find skilled partners for machining services depending on their tools, previous experience, and overall satisfaction level of clients to achieve the best outcome of the work done.

This is a basic explanation and introduction guide to CNC machining that covers all the necessary information. With some luck, this summary will help you understand the potential of this technology and how it will help you in your further projects.